Senya 3

KEY SPECS: | |

Capacity | 20 - 30 tph |

| Jaw Opening | 19" x 11" |

Input Size | < 13" |

| Output Size | ¾" - 3" minus |

Weight | 14,000 lbs |

Power System | Electrically Driven |

| Working Dimension | 22' L x 7' W x 8.5' H |

Call for custom quote.

Price Starting at:

$98,500+

Financing from:

$1,910/mo

(Example based on 60-month loan at 5% interest.)

Lead Time:

Shipping:

Warranty:

1 week

4-7 days

1 year

(Shipped from main equipment yard in Raleigh, NC.)

The small-sized Senya 3 MICRO Jaw Crusher is our entry level crusher and can produce 200-300 tons per day (realistically filling 1 dump truck per hour minimum). Our customer’s reported average ROI is 4 months with $225,000+ 1st year savings at ~15 truckloads per month.

For larger scale crushing (60-80 tph), see the Senya 6 MICRO Jaw Crusher.

For screening 3 sizes of material to usable/salable spec products, see the SP1 MICRO Screen Plant.

Features a simpler engineering design and electrically driven system to offer the industry’s lowest long-term running costs, cost of ownership and greatest profitability.

Industries: We have a wide range of customers from small-to-mid sized contractors, aggregate producers, and mining operations — from demolition, construction, excavation, landscaping, agriculture, etc.

Applications & Use Cases: Whether it’s recycling concrete or asphalt, producing base aggregate, decorative rock, granite countertop scrap, recycling glass, slag, and on-and-on — the applications and income producing possibilities of our MICRO Crushers are endless.

Contractors:

* Eliminate disposal, trucking & aggregate costs.

* Create an additional revenue stream.

* Control your costs & production.

Producers:

* Improve efficiency and profitability.

* Cut down fuel costs and maintenance.

* Maximize your production while minimizing downtime.

(Video below shows the last of our orange crushers. New ’23 models are green.)

Configuration: Jaw crusher

Power System: Electrically-Driven via Onboard Genset

Yanmar 40kW Generator: SELF CONTAINED, 40 kW, 50 hp

Total Power (required): 24 hp, 480 v, 60 Hz

Electrical Control: Yes, wireless remote standard

Hydraulic Control: No hydraulics

Capacity: 20-30 tph

Crushing material: Granite, river rock, limestone, concrete, asphalt, etc.

Jaw Feed Opening: 19″ x 11″

Feed Input Size: ˂ 13″

Product Output Size: ¾” – 3″ Minus

Feeding Height: 8.5 ft

Hopper Volume: 1.5 cu yds

Working Dimension (LxWxH): 22′ L x 7′ W x 8′ 6″ H

Conveyor Belt: 1

Magnet: Optional

Dust Suppression: Optional

Weight: 14,000 lbs

Assembly time: Less than 10 minutes

Portability: Tire / ¾ Ton Pickup (pintle hook)

Road Legal: Yes

Key Features & Benefits

1. Unmatched crushing power, over X2 our competition! — With 14,000 lbs of shear brute force and massive flywheels, this machine eats through the hardest material like it’s popcorn! Have customers crushing river rock and granite all the time (on 7-8 Mohs hardness scale).

2. Electrically-Driven via legendary Yanmar 40kW Onboard Generator – American made, warrantied & serviced — USA made Self-Contained Generator installed inside the machine, just under the feeder. All motors are electric and powered by the generator — NO HYDRAULICS to Service! NO high maintenance costs! RUNS ALL DAY ON $40 of diesel fuel!! Extremely efficient, minimal wear & tear, reduced fuel costs, increased lifespan, and negligible maintenance. Yanmar 4TNV98C-GGE Engine, TIER 4 FINAL Certified Diesel Engine lasts “almost forever.”

3. Low fuel costs & high production capabilities — Runs ALL DAY on less than $30-40 in fuel while easily producing 200-300 tons of aggregate per day.

4. Service and maintenance costs are nearly zero — NO Hydraulics to service, NO high maintenance costs, no DEF fluid, and no track undercarriage to worry about. Affordable and easy replacement of high wear parts. (Only 3 high wear parts: jaw, conveyor belt, and flywheel drive belts.)

5. Simple to maintain & easy to operate with straightforward controls — Anybody can learn to operate this machine and up to speed in 30 minutes. Control the crusher with the wireless remote while loading from a skid steer, easily run by a single operator! USA Made Diesel Generator control panel is integrated into the machine control panel providing the maximum in protection with low level warnings as well as ease of start up.

6. 100% portable & quick set-up times — Pull with a pickup, drop the legs and start crushing in 10 minutes or less. No need for prime movers or trailers, and the entire thing could easily be moved several times a day.

7. Yanmar 40kW Generator Powers The Entire Micro Plant — “Plug & Play”; the MICRO Crusher, Screen Plant and 3 Conveyors can ALL be powered by this generator! Extremely cost-effective and efficient compared to traditional diesel/hydraulically driven machines.

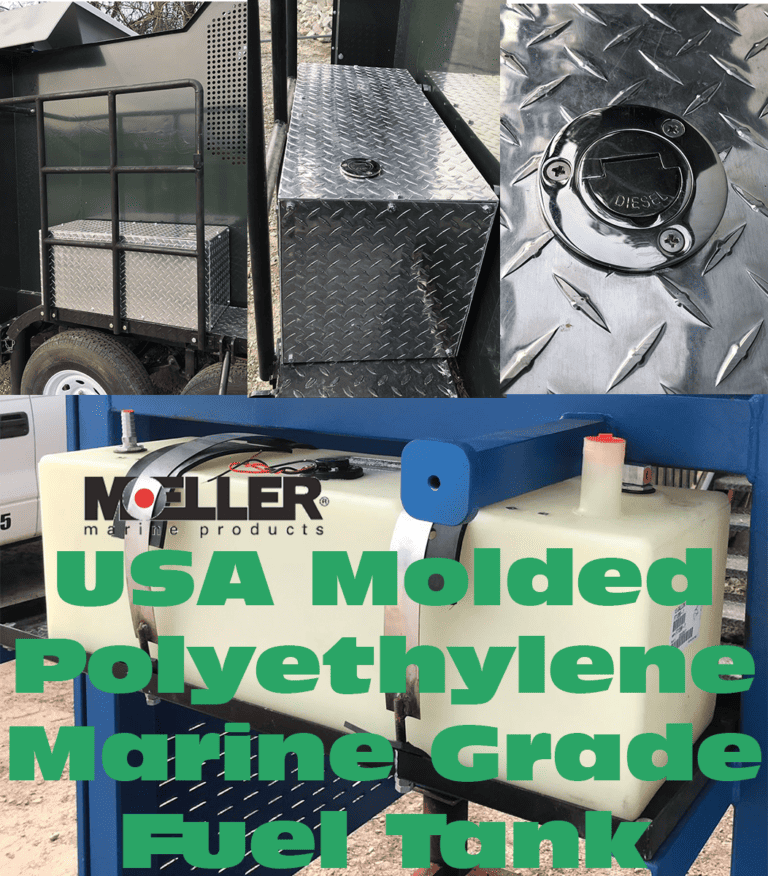

8. USA Molded Marine Grade Moeller Fuel Tank — Fuel consumption is 1/2 – 3/4 gallon per hour, runs all day on less than $30-40 of fuel.

9. Massive Flywheels Generate Unmatched Crushing Power! — THERE’S A REASON OUR MACHINE WEIGHS TWICE THAT OF OUR COMPETITORS MACHINES, FOR X2 RAW CRUSHING POWER! Lower maintenance costs, greater durability.

10. Integrated Single Piece Motor Mount And Jaw Frame

11. Single Piece 5x Banded V Belt

12. Heavy Duty Footpads Included With Every Crusher

13. Heavy Duty Feeder Wear Plates

14. Upgraded Oversized Vibratory Motors And Reinforced HD Motor Mount Design

X2 electric vibratory motors are installed under the 1” thick steel feeding hopper to move the material feed flow into the jaw opening quickly and efficiently.

Doesn’t need a feed sensor to turn off/on a conveyor belt feeder and control the flow of material in order to prevent jamming — like other options on the market. This is due to our machine’s unmatched X2 crushing power & X2 weight that allows you to completely fill the hopper and jaw’s crushing chamber cavity full of material — and to benefit from the additional compressing force of gravity to enhance the crushing process, not let material to throw back up, and achieve maximum crushing efficiency & TPH output.

15. Heavy Duty 8 Lug Rims And 16 Ply Tires

16. 16k Lb. Axle Capacity On 14k Lb. Machine!

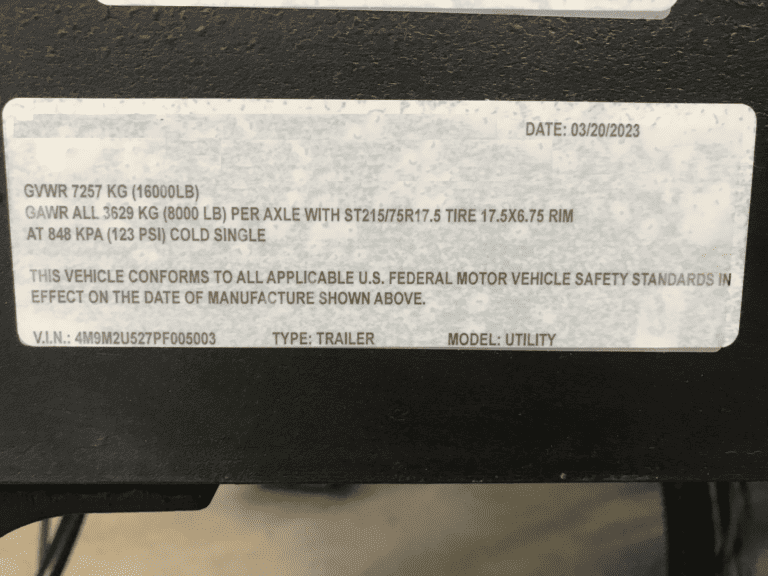

17. DOT Approved And Vin’d Usa Designed And Manufactured Trailer

18. Break Away Electric Brake System

19. US Standard 3″ Lunette Ring Hitch

20. 12k lb. capacity HD Leg Jacks — Allows you to stabilizing your crusher by adjusting the leg jacks to put weigh primarily on tires to ensure a trouble free operation.

21. Control Panel Includes Wireless Remote

22. Dust Suppression System Optional Add-On

Optional Add-Ons:

23. Magnetic Conveyor Attachment Optional Add-On for Senya 3 – COMING SOON!

Optional Add-On: $3,500 without frame, $5,000 with frame.

24. Integrated 50 Amps Of 110v Step Down Transformer – COMING SOON! — Remote on-site power.

25. DOT Approved Radial Yard Upgrade Option to our MICRO Conveyor – COMING SOON!

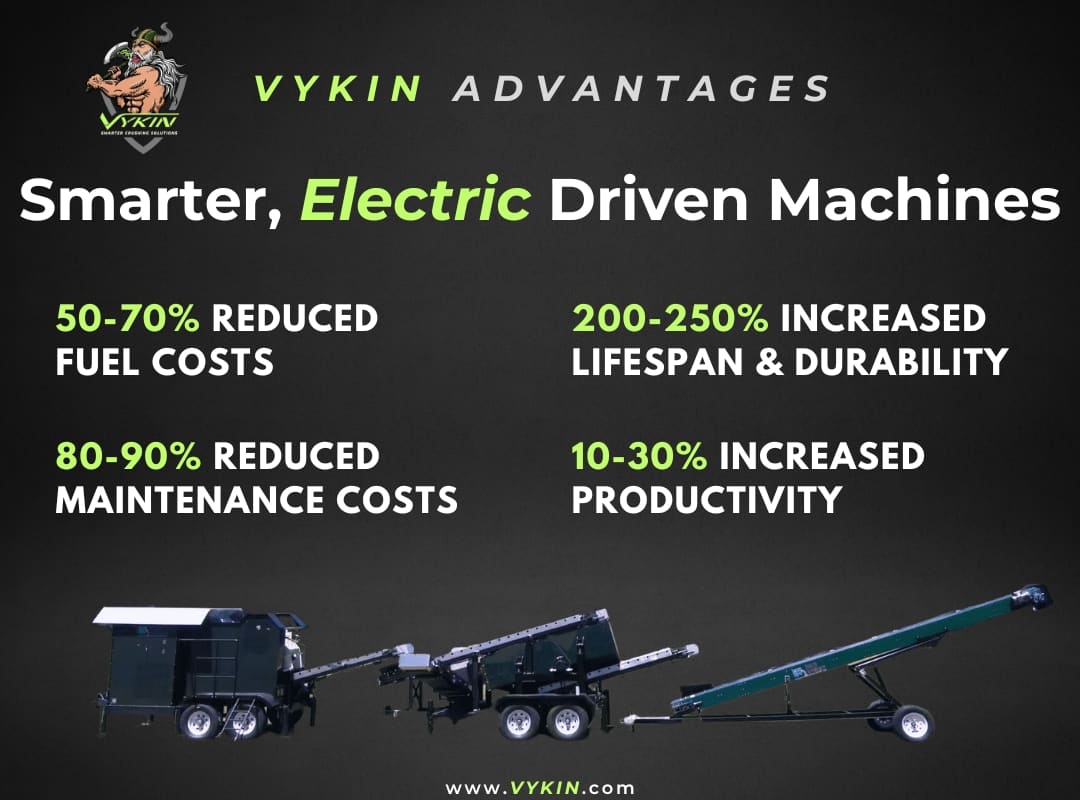

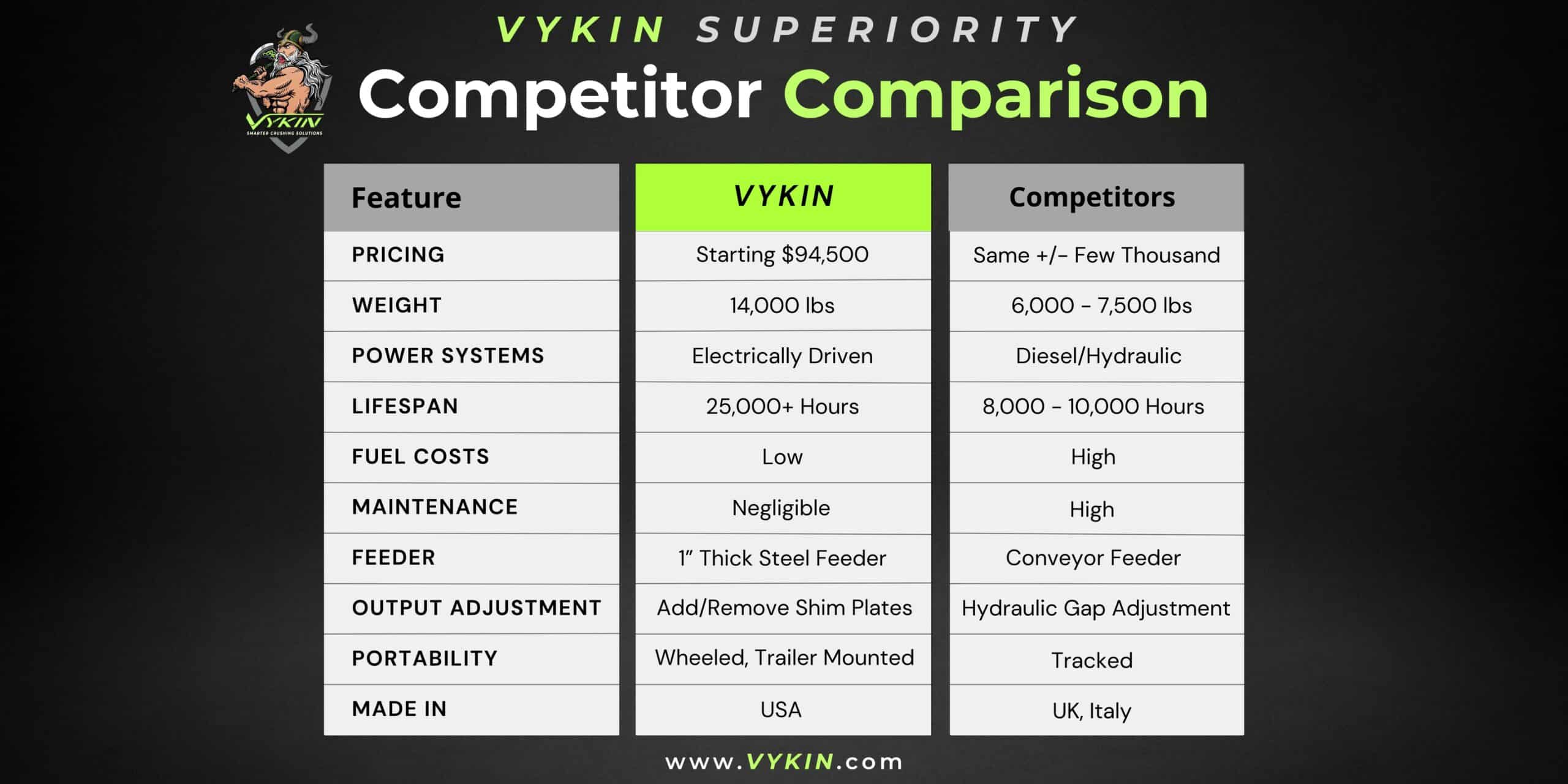

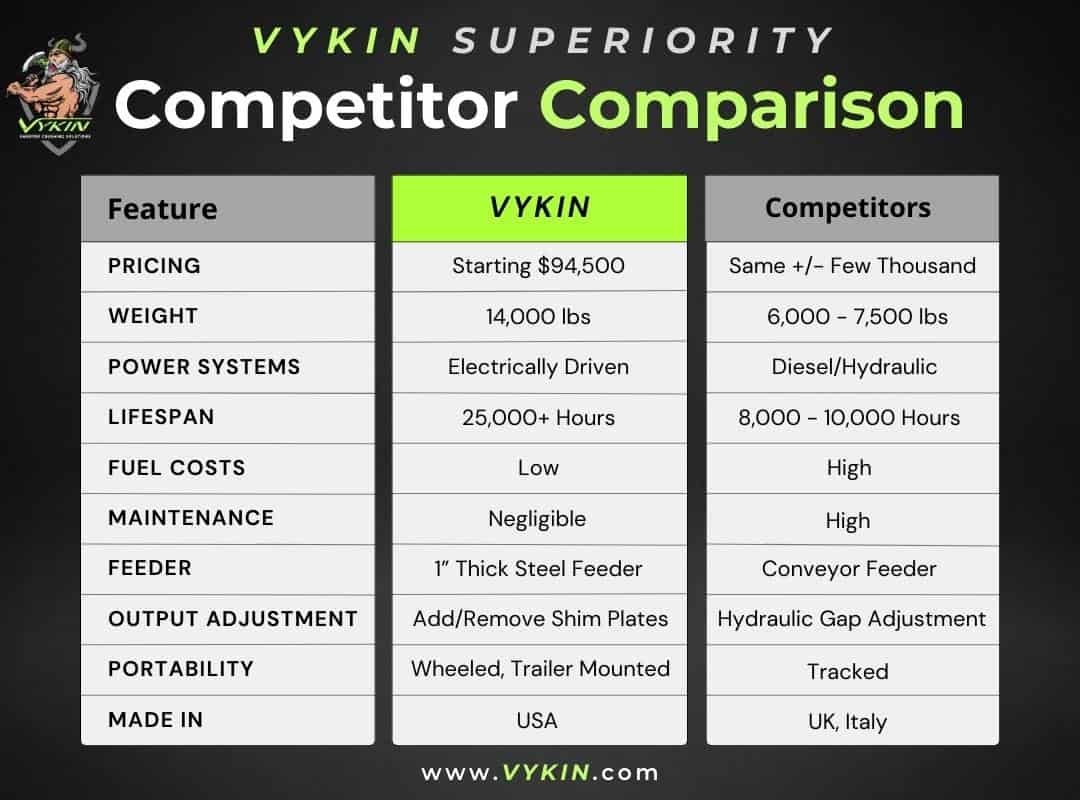

Achieve TRIPLE Bottomline Savings

With VYKIN‘s Smarter Crushers

Our crushers are smarter & simpler by design and feature an electrically driven power system (all electric motors, powered via genset — or optional, mains electric if available).

In direct comparison to other traditional diesel/hydraulically powered crushers, when the calculation is done right — dollar for dollar — you can’t beat our electrically powered crushers in terms of true cost of ownership.

We are able to offer our customer’s the industry’s lowest long-term running costs due to the benefits of electrical efficiency & reliability and utilizing a simpler engineering design. Easily a X3 greater cost-savings over time on lifespan, running costs, and maintenance.

Below you can learn more about the advantages & benefits of owning a simpler & smarter, electric driven machine:

Not all crushers are created equal and the differences are significant.

A lot of manufacturers still use diesel/hydraulic drive systems for the track-drive and power to the crusher; inefficient power systems utilizing high maintenance & problematic onboard Diesel engines and energy-intensive & high cost Hydraulic drive components — we don’t. (In the maintenance section, we will further explain why.)

Significant savings in fuel costs costs come from the extreme 95% efficiency of our electric motors (compare to 45% with diesel engines).

The control panel gives you a read on fuel consumption:

Plus, you have the added benefit of running your micro screen plant and all 3 conveyors from 1 single power source (using your crusher’s existing genset).

For additional cost savings, the micro screen plant and conveyors were all designed to run off of the crusher’s genset as your 1 single power source. This results in even bigger savings, better overall efficiency, much lower costs and significantly reduced maintenance & downtime — because you only having to service 1 machine (the genset) as opposed to each separate unit.

(Whereas with traditional diesel/hydraulic plants with onboard Diesel engines & hydraulic systems that are high maintenance & always problems, if you had 5 different units, you would have to service & maintain all 5 of them further adding to your total costs, complexity and x5 more potential problems.)

Most machines today on the market have become very high-tech, increasingly complex and more expensive to run — and suffer from regular downtime due to high level of maintenance and overall a lot more to go wrong. It’s like buying a technology nightmare with 30+ minutes spent on daily maintenance with hydraulics alone.

Even on regular machines, hydraulics is a pain — but add the high vibration in crushing equipment, especially in compact spaces, and it’s a troubleshooting nightmare for hydraulic systems. Something is bound to fail with traditional diesel/hydraulic machines — frequent downtime, repairs, maintenance and constant problems.

By direct comparison, our electric driven machines are more simply-designed machines, very straightforward and incredible easy to operate & maintain. We’ve done away with complicated and problematic hydraulic components, computerized parts, sensors, etc — They are a lot less complicated than the other options on the market, but that is what makes our machines simple, reliable and overall bulletproof machines.

All motors are electric (little to no wear & tear) and powered by the toughest Yanmar generator we make. NO hydraulics, and with fewer moving parts, there is less to go wrong — the beauty of our machines is in its simplicity! The only high wear parts are the jaw plates themselves, then the conveyor belts and lastly the flywheel belts. Our electrically driven machines an order of magnitude more reliable for that reason.

In terms of daily maintenance, 2 minutes to grease the jaws & flywheel bearings on the side housing. And every 6-12 months, quickly check the grease in the drive motors for flywheels and conveyor drive rollers.

Crushing is a rough business. 99% of all problems with crushing equipment is due to the high vibration of the unit (“shaking to death”). So being able to stabilize your crusher is the #1 solution to keeping your machine trouble free & extremely reliable. And we are able to achieve peace of mind for our customers in 3 ways:

That will make your crusher as smooth as a whistle. You cannot do that on a regular tracked unit.

Traditional diesel/hydraulic driven machines last between 8,000 – 10,000 hours until they reach the end of their life cycle or become unreliable with extensive downtime, repairs, and lost productions needs into profit margins.

Our electrically driven machines can last beyond 25,000+ hours AND can easily be refurbished to remove worn parts & turn into a new machine again.

The average life cycle alone is nearly a X3 difference! Plus our machines can last in perpetuity as every high wear part can be either replaced or rebuilt affordable, without needing to replace the entire unit.

The rate of depreciation for diesel/hydraulic units on the market is X3 faster than our electric powered models. So with our machines, you have an investment that holds its value over time, has a higher re-sale value, and has a considerably longer productive life over it entire cycle.

This is what makes Vykin’s electric driven machines smarter because all things considered — with increased efficiency, better uptime & reliability, reduced maintenance and greater lifespan — you have a more productive (and profitable) machine.

When you calculate the true costs of our electric powered crushers VS traditional diesel/hydraulic crushers — the total initial Purchase price + total Ownership & Operation cost over the entire life cycle — our machines offer nearly a X3 greater bottomline savings for our customers.

Environmental Advantages with Low/No Emissions — Especially important for government, municipal, and metropolitan areas with emission targets & carbon regulations.

Due to aggressive carbon reduction targets, green movement regulations, increasing pollution, and global warming — the government, municipalities and legislation is starting to implement greener policies.

This means 2 important things:

Not all crushers are created equal and the differences are significant.

A lot of manufacturers still use diesel/hydraulic drive systems for the track-drive and power to the crusher; inefficient power systems utilizing high maintenance & problematic onboard Diesel engines and energy-intensive & high cost Hydraulic drive components — we don’t. (In the maintenance section, we will further explain why.)

Significant savings in fuel costs costs come from the extreme 95% efficiency of our electric motors (compare to 45% with diesel engines).

The control panel gives you a read on fuel consumption:

Plus, you have the added benefit of running your micro screen plant and all 3 conveyors from 1 single power source (using your crusher’s existing genset).

For additional cost savings, the micro screen plant and conveyors were all designed to run off of the crusher’s genset as your 1 single power source. This results in even bigger savings, better overall efficiency, much lower costs and significantly reduced maintenance & downtime — because you only having to service 1 machine (the genset) as opposed to each separate unit.

(Whereas with traditional diesel/hydraulic plants with onboard Diesel engines & hydraulic systems that are high maintenance & always problems, if you had 5 different units, you would have to service & maintain all 5 of them further adding to your total costs, complexity and x5 more potential problems.)

Most machines today on the market have become very high-tech, increasingly complex and more expensive to run — and suffer from regular downtime due to high level of maintenance and overall a lot more to go wrong. It’s like buying a technology nightmare with 30+ minutes spent on daily maintenance with hydraulics alone.

Even on regular machines, hydraulics is a pain — but add the high vibration in crushing equipment, especially in compact spaces, and it’s a troubleshooting nightmare for hydraulic systems. Something is bound to fail with traditional diesel/hydraulic machines — frequent downtime, repairs, maintenance and constant problems.

By direct comparison, our electric driven machines are more simply-designed machines, very straightforward and incredible easy to operate & maintain. We’ve done away with complicated and problematic hydraulic components, computerized parts, sensors, etc — They are a lot less complicated than the other options on the market, but that is what makes our machines simple, reliable and overall bulletproof machines.

All motors are electric (little to no wear & tear) and powered by the toughest Yanmar generator we make. NO hydraulics, and with fewer moving parts, there is less to go wrong — the beauty of our machines is in its simplicity! The only high wear parts are the jaw plates themselves, then the conveyor belts and lastly the flywheel belts. Our electrically driven machines an order of magnitude more reliable for that reason.

In terms of daily maintenance, 2 minutes to grease the jaws & flywheel bearings on the side housing. And every 6-12 months, quickly check the grease in the drive motors for flywheels and conveyor drive rollers.

Crushing is a rough business. 99% of all problems with crushing equipment is due to the high vibration of the unit (“shaking to death”). So being able to stabilize your crusher is the #1 solution to keeping your machine trouble free & extremely reliable. And we are able to achieve peace of mind for our customers in 3 ways:

That will make your crusher as smooth as a whistle. You cannot do that on a regular tracked unit.

Traditional diesel/hydraulic driven machines last between 8,000 – 10,000 hours until they reach the end of their life cycle or become unreliable with extensive downtime, repairs, and lost productions needs into profit margins.

Our electrically driven machines can last beyond 25,000+ hours AND can easily be refurbished to remove worn parts & turn into a new machine again.

The average life cycle alone is nearly a X3 difference! Plus our machines can last in perpetuity as every high wear part can be either replaced or rebuilt affordable, without needing to replace the entire unit.

The rate of depreciation for diesel/hydraulic units on the market is X3 faster than our electric powered models. So with our machines, you have an investment that holds its value over time, has a higher re-sale value, and has a considerably longer productive life over it entire cycle.

This is what makes Vykin’s electric driven machines smarter because all things considered — with increased efficiency, better uptime & reliability, reduced maintenance and greater lifespan — you have a more productive (and profitable) machine.

When you calculate the true costs of our electric powered crushers VS traditional diesel/hydraulic crushers — the total initial Purchase price + total Ownership & Operation cost over the entire life cycle — our machines offer nearly a X3 greater bottomline savings for our customers.

Environmental Advantages with Low/No Emissions — Especially important for government, municipal, and metropolitan areas with emission targets & carbon regulations.

Due to aggressive carbon reduction targets, green movement regulations, increasing pollution, and global warming — the government, municipalities and legislation is starting to implement greener policies.

This means 2 important things:

1. You get X2 more value for your money!

Even at similar purchase prices, our crusher is overbuilt from top to bottom weighing X2 more than all other options on the market — and our machines don’t even having tracks!

2. You get twice as much crushing power!

There’s a reason our machine weighs double what our competition does (even with theirs having tracks), it’s due to our massive flywheels and jaws — which generates that massive crushing power.

Crushing power = output rate productivity as well as durability, longevity & low maintenance costs, and it’s all about the mass/weight.

So when we say our crusher has a production capacity of 20-30 tph, it is realistic. That also explains why we don’t need a feed sensor to control material feed flow because our machines don’t jam or have an issue with a crushing chamber cavity full of material and can crush anything without even breaking a sweat!

3. You get a machine that is easier to maintain & easier to operate.

NO hydraulics to service, no high maintenance, no high running costs, no problematic onboard diesel engine, no added transportation costs, no sensor issues with dust — like with other options on the market (with tracks, hydraulic jaw adjustment, needing prime mover to transport, etc).

No constant problems or high wear & tear from the high vibration of crushing due to major stabilization features that a tracked unit simply cannot do.

No needing to replace your feeder wear plates (unlike having a conveyor feeder, which is destined for problems as belt will quickly wear from material being dropped on it, especially from inevitable high height).

4. You get a more economical & cost-efficient machine.

You get the best possible performance at the lowest long-term cost of ownership with Vykin’s smarter electric driven machines.

With X3 greater bottomline cost-savings on maintenance, running costs and overall lifespan — our electrically driven crushers are superior to any traditional diesel/hydraulically driven units on the market.

To sum up: the beauty of our electric driven machines is in its simplicity — there is little to go wrong! Negligible maintenance. No hydraulic problems. Peace of mind. More time spent crushing and less time spent troubleshooting.

Most machines today on the market have become very high-tech, increasingly complex and more expensive to run — there is lots to go wrong and suffer from regular downtime due to levels of high maintenance. Hydraulic components are a pain in regular machines, but add high vibration and something that essentially “shakes itself to death,” and it’s a troubleshooting nightmare with constant problems. Something is bound to go wrong with traditional diesel/hydraulic driven machines.

But don’t let appearances and a simpler design behind our machines fool you. Our partner has been manufacturing crushing and screening equipment since 1955 from micro machines to massive $10M+ plants. This is an intentional engineering decision based on 65+ years of manufacturing expertise to create a smarter crushing solution for customers. Built proven to be a reliably durable workhorse and extremely cost-efficient with X3 greater lifetime cost-savings compared to any other comparable options on the market.

You can use our Cashflow Calculator to input your numbers to get a realistic idea of your Cost-Savings & ROI payback period using this equipment.

Price Starts At: $94,500 ($61,425 NET cost with Section 179)

Financed: $1,910/mo

Financing Available: Click here to start your financing application.

More Ways to Save: Qualifies for 100% capital equipment deductions with Section 179.

Let Uncle Sam pay for ⅓ of the cost of your crusher!

How much money can Section 179 save you?

Total First Year Deduction: $94,500

Cash Savings on your Purchase: $33,075

Lowered Cost of Equipment: $61,425

(after Tax Savings)

On-Site Training: Shortly after delivery, we will send out one of our guys to get you up to speed on your crusher. You will also have access to setup videos you can watch in the meantime.

Service: We are always just 1 call away for help, assistance or questions! For any issues we can’t resolve over the phone or video call, we will fly out a technician to your site.

Parts: Always have wear parts in stock and ready to ship out same day or within next day depending on urgency required.

Warranty:

High wear parts:

Operating costs:

Because maintenance is negligible, your primary ongoing costs will be fuel:

Videos are automatically muted.

Video #1 – Part 1

Customer crushing granite:

Video #1 – Part 2

Customer crushing granite:

Video #1 – Part 3

Customer crushing granite:

Granite ¾” minus final product:

Video #2

Customer crushing concrete:

– Wear parts & pricing

– Ongoing expenses (fuel mainly)

– Maintenance

– Financing

Not all crushers are created equal and the differences are significant.

A lot of manufacturers still use diesel/hydraulic drive systems for the track-drive and power to the crusher; inefficient power systems utilizing high maintenance & problematic onboard Diesel engines and energy-intensive & high cost Hydraulic drive components — we don’t. (In the maintenance section, we will further explain why.)

Significant savings in fuel costs costs come from the extreme 95% efficiency of our electric motors (compare to 45% with diesel engines).

The control panel gives you a read on fuel consumption:

Plus, you have the added benefit of running your micro screen plant and all 3 conveyors from 1 single power source (using your crusher’s existing genset).

For additional cost savings, the micro screen plant and conveyors were all designed to run off of the crusher’s genset as your 1 single power source. This results in even bigger savings, better overall efficiency, much lower costs and significantly reduced maintenance & downtime — because you only having to service 1 machine (the genset) as opposed to each separate unit.

(Whereas with traditional diesel/hydraulic plants with onboard Diesel engines & hydraulic systems that are high maintenance & always problems, if you had 5 different units, you would have to service & maintain all 5 of them further adding to your total costs, complexity and x5 more potential problems.)

Most machines today on the market have become very high-tech, increasingly complex and more expensive to run — and suffer from regular downtime due to high level of maintenance and overall a lot more to go wrong. It’s like buying a technology nightmare with 30+ minutes spent on daily maintenance with hydraulics alone.

Even on regular machines, hydraulics is a pain — but add the high vibration in crushing equipment, especially in compact spaces, and it’s a troubleshooting nightmare for hydraulic systems. Something is bound to fail with traditional diesel/hydraulic machines — frequent downtime, repairs, maintenance and constant problems.

By direct comparison, our electric driven machines are more simply-designed machines, very straightforward and incredible easy to operate & maintain. We’ve done away with complicated and problematic hydraulic components, computerized parts, sensors, etc — They are a lot less complicated than the other options on the market, but that is what makes our machines simple, reliable and overall bulletproof machines.

All motors are electric (little to no wear & tear) and powered by the toughest Yanmar generator we make. NO hydraulics, and with fewer moving parts, there is less to go wrong — the beauty of our machines is in its simplicity! The only high wear parts are the jaw plates themselves, then the conveyor belts and lastly the flywheel belts. Our electrically driven machines an order of magnitude more reliable for that reason.

In terms of daily maintenance, 2 minutes to grease the jaws & flywheel bearings on the side housing. And every 6-12 months, quickly check the grease in the drive motors for flywheels and conveyor drive rollers.

Crushing is a rough business. 99% of all problems with crushing equipment is due to the high vibration of the unit (“shaking to death”). So being able to stabilize your crusher is the #1 solution to keeping your machine trouble free & extremely reliable. And we are able to achieve peace of mind for our customers in 3 ways:

That will make your crusher as smooth as a whistle. You cannot do that on a regular tracked unit.

Traditional diesel/hydraulic driven machines last between 8,000 – 10,000 hours until they reach the end of their life cycle or become unreliable with extensive downtime, repairs, and lost productions needs into profit margins.

Our electrically driven machines can last beyond 25,000+ hours AND can easily be refurbished to remove worn parts & turn into a new machine again.

The average life cycle alone is nearly a X3 difference! Plus our machines can last in perpetuity as every high wear part can be either replaced or rebuilt affordable, without needing to replace the entire unit.

The rate of depreciation for diesel/hydraulic units on the market is X3 faster than our electric powered models. So with our machines, you have an investment that holds its value over time, has a higher re-sale value, and has a considerably longer productive life over it entire cycle.

This is what makes Vykin’s electric driven machines smarter because all things considered — with increased efficiency, better uptime & reliability, reduced maintenance and greater lifespan — you have a more productive (and profitable) machine.

When you calculate the true costs of our electric powered crushers VS traditional diesel/hydraulic crushers — the total initial Purchase price + total Ownership & Operation cost over the entire life cycle — our machines offer nearly a X3 greater bottomline savings for our customers.

Environmental Advantages with Low/No Emissions — Especially important for government, municipal, and metropolitan areas with emission targets & carbon regulations.

Due to aggressive carbon reduction targets, green movement regulations, increasing pollution, and global warming — the government, municipalities and legislation is starting to implement greener policies.

This means 2 important things:

Not all crushers are created equal and the differences are significant.

A lot of manufacturers still use diesel/hydraulic drive systems for the track-drive and power to the crusher; inefficient power systems utilizing high maintenance & problematic onboard Diesel engines and energy-intensive & high cost Hydraulic drive components — we don’t. (In the maintenance section, we will further explain why.)

Significant savings in fuel costs costs come from the extreme 95% efficiency of our electric motors (compare to 45% with diesel engines).

The control panel gives you a read on fuel consumption:

Plus, you have the added benefit of running your micro screen plant and all 3 conveyors from 1 single power source (using your crusher’s existing genset).

For additional cost savings, the micro screen plant and conveyors were all designed to run off of the crusher’s genset as your 1 single power source. This results in even bigger savings, better overall efficiency, much lower costs and significantly reduced maintenance & downtime — because you only having to service 1 machine (the genset) as opposed to each separate unit.

(Whereas with traditional diesel/hydraulic plants with onboard Diesel engines & hydraulic systems that are high maintenance & always problems, if you had 5 different units, you would have to service & maintain all 5 of them further adding to your total costs, complexity and x5 more potential problems.)

Most machines today on the market have become very high-tech, increasingly complex and more expensive to run — and suffer from regular downtime due to high level of maintenance and overall a lot more to go wrong. It’s like buying a technology nightmare with 30+ minutes spent on daily maintenance with hydraulics alone.

Even on regular machines, hydraulics is a pain — but add the high vibration in crushing equipment, especially in compact spaces, and it’s a troubleshooting nightmare for hydraulic systems. Something is bound to fail with traditional diesel/hydraulic machines — frequent downtime, repairs, maintenance and constant problems.

By direct comparison, our electric driven machines are more simply-designed machines, very straightforward and incredible easy to operate & maintain. We’ve done away with complicated and problematic hydraulic components, computerized parts, sensors, etc — They are a lot less complicated than the other options on the market, but that is what makes our machines simple, reliable and overall bulletproof machines.

All motors are electric (little to no wear & tear) and powered by the toughest Yanmar generator we make. NO hydraulics, and with fewer moving parts, there is less to go wrong — the beauty of our machines is in its simplicity! The only high wear parts are the jaw plates themselves, then the conveyor belts and lastly the flywheel belts. Our electrically driven machines an order of magnitude more reliable for that reason.

In terms of daily maintenance, 2 minutes to grease the jaws & flywheel bearings on the side housing. And every 6-12 months, quickly check the grease in the drive motors for flywheels and conveyor drive rollers.

Crushing is a rough business. 99% of all problems with crushing equipment is due to the high vibration of the unit (“shaking to death”). So being able to stabilize your crusher is the #1 solution to keeping your machine trouble free & extremely reliable. And we are able to achieve peace of mind for our customers in 3 ways:

That will make your crusher as smooth as a whistle. You cannot do that on a regular tracked unit.

Traditional diesel/hydraulic driven machines last between 8,000 – 10,000 hours until they reach the end of their life cycle or become unreliable with extensive downtime, repairs, and lost productions needs into profit margins.

Our electrically driven machines can last beyond 25,000+ hours AND can easily be refurbished to remove worn parts & turn into a new machine again.

The average life cycle alone is nearly a X3 difference! Plus our machines can last in perpetuity as every high wear part can be either replaced or rebuilt affordable, without needing to replace the entire unit.

The rate of depreciation for diesel/hydraulic units on the market is X3 faster than our electric powered models. So with our machines, you have an investment that holds its value over time, has a higher re-sale value, and has a considerably longer productive life over it entire cycle.

This is what makes Vykin’s electric driven machines smarter because all things considered — with increased efficiency, better uptime & reliability, reduced maintenance and greater lifespan — you have a more productive (and profitable) machine.

When you calculate the true costs of our electric powered crushers VS traditional diesel/hydraulic crushers — the total initial Purchase price + total Ownership & Operation cost over the entire life cycle — our machines offer nearly a X3 greater bottomline savings for our customers.

Environmental Advantages with Low/No Emissions — Especially important for government, municipal, and metropolitan areas with emission targets & carbon regulations.

Due to aggressive carbon reduction targets, green movement regulations, increasing pollution, and global warming — the government, municipalities and legislation is starting to implement greener policies.

This means 2 important things:

Add the MICRO Screen Plant and MICRO Conveyor for the entire MICRO Plant — producing and sorting three sizes at 200-300 tons per day, loading directly to the dump trucks, and run & loaded by a single operator with remote and a skid steer!

For larger scale crushing (60-80 tph), see the Senya 6 Jaw Crusher.

For screening 3 sizes of material to usable/salable spec products, see the Micro Screen Plant SP1.

Small Mobile Gravel Crushers For Sale $1.8K/mo — Versatile, Easy to Use, Setup & Move. Our Gravel Crushers Are Ideal, Affordable Solutions For A Wide Range Of Job Applications. Profitably Crush On-Site, Eliminate Disposal Costs & Use Base Aggregate for Huge Savings.

$98,500.00