Starting at $22,000+

Lead time 4 months*

*Due to the shortage of semiconductors, new models released June/July 2023.

See spec sheet for pricing & available models.

Hydraulic Magnet Pulverizer.

No Electrical Wiring Required.

Quickly reduce massive concrete slabs into manageable pieces for your crusher — while also removing any rebar.

Proper material prep is essential to prevent downtime from blockages and ensure a productive crushing operation.

Pulverizer has a built in blade to cut oversized strands of rebar and separate it from your material.

No Customization and Additional Battery/Generator required.

Whereas conventional types require modifications such as electrical wiring to excavator body side, MAG-GON does not require any customization.

MAG-GON can work immediately after installation, regardless of type of hydraulic excavator. No additional batteries or generators are required.

Big cylinders and Acceleration valve.

MC Series with big cylinders and Acceleration valve realizes pulverizing work with low-vibration and low-noise. TAGUCHI’s unique design to place hyd. cylinder inside the main body enable to work without worrying about damage to the rod. Acceleration valve (jaw closing) is standard in all models and it bring improving work efficiency.

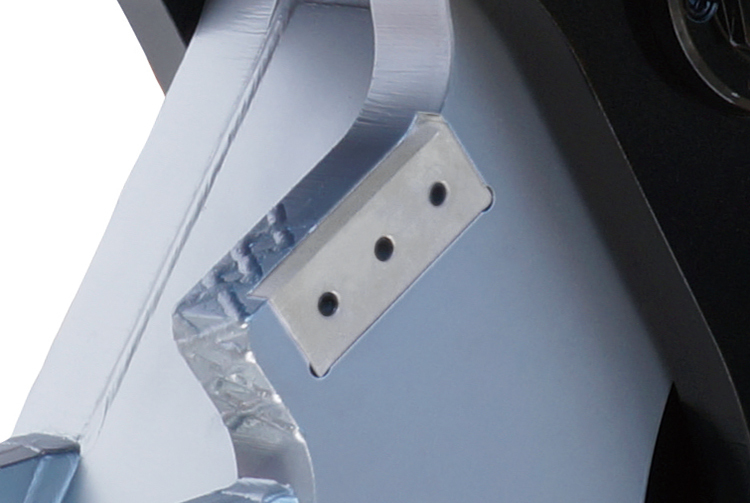

Easy Maintenance. Special Steel Blade.

The special steel blade as standard feature can be used on 4 sides reversible. It is possible to cut the rebar that appears during pulverizing work. The tooth is also made of special steel and it is easy to replace and repair.

SPECS

| Model Name | Class of excavator[ton] | Operating pressure[MPa] | Max. operating pressure[MPa] | Length A[mm] | Max. jaw opening B[mm] | Cutting blade length C[mm] | Crushing force at tip D[kN] | Crushing force at center E[kN] | Magnet duty cycle[%ED] | Magnet power consumption[kW] | Magnet diameter F[mm] | Mass[kg] | Approximate lifting capacity[kg] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

MC-36BM2C | 3 – 5 ton $22,780 | 24.5 | 24.5 | 955 | 430 | 70 | 178 | 282 | 50 (Repeating cycle of power on 5 minutes and pause 5 minutes) | 0.1 | φ200 | 280 | Pig iron:10kg, Steel plate cut layer:8kg, Chips:2kg |

MC-75DM5A | 6 – 8 ton $44,700 | 24.5 | 27.4 | 1390 | 620 | 100 | 369 | 534 | 60 (Repeating cycle of power on 6 minutes and pause 4 minutes) | 1.0 | φ500 | 940 | Pig iron:120kg, Steel plate cut layer:90kg, Chips:25kg |

MC-135EM5A | 10 – 14 ton $47,390 | 31.4 | 34.3 | 1600 | 750 | 120 | 549 | 882 | 60 (Repeating cycle of power on 6 minutes and pause 4 minutes) | 1.0 | φ500 | 1440 | Pig iron:120kg, Steel plate cut layer:90kg, Chips:25kg |

MC-212EM7A | 20 – 22 ton $53,400 | 31.4 | 34.3 | 1880 | 880 | 160 | 715 | 1150 | 60 (Repeating cycle of power on 6 minutes and pause 4 minutes) | 3.3 | φ700 | 2400 | Pig iron:350kg, Steel plate cut layer:200kg, Chips:100kg |

MC-352EM7A | 30 – 35 ton $66,550 | 31.4 | 34.3 | 2320 | 1100 | 180 | 1080 | 1770 | 60 (Repeating cycle of power on 6 minutes and pause 4 minutes) | 3.3 | φ700 | 3570 | Pig iron:350kg, Steel plate cut layer:200kg, Chips:100kg |

MC-352EM9A | 30 – 35 ton $75,990 | 31.4 | 34.3 | 2320 | 1100 | 180 | 1080 | 1770 | 60 (Repeating cycle of power on 6 minutes and pause 4 minutes) | 6.2 | φ900 | 3870 | Pig iron:500kg, Steel plate cut layer:300kg, Chips:200kg |

・Single two-way hydraulic piping is required.

・MC-36BM2C adopts DC12V battery.

・We recommend reinforcing the arm of a hydraulic excavator that has the Guzzilla series installed.

・The attachment cannot be installed on a hydraulic excavator of a different class.

・Please consult us about the hydraulic excavator class to attach the product.