Are you in the market for a new asphalt crusher? If so, read our best practices for crushing and screening before you make your purchase. By following these tips, you’ll be able to choose the suitable crusher for your needs and get the most out of your investment. So what are you waiting for? Read on to learn more!

What Is An Asphalt Crusher, And What Are Its Uses?

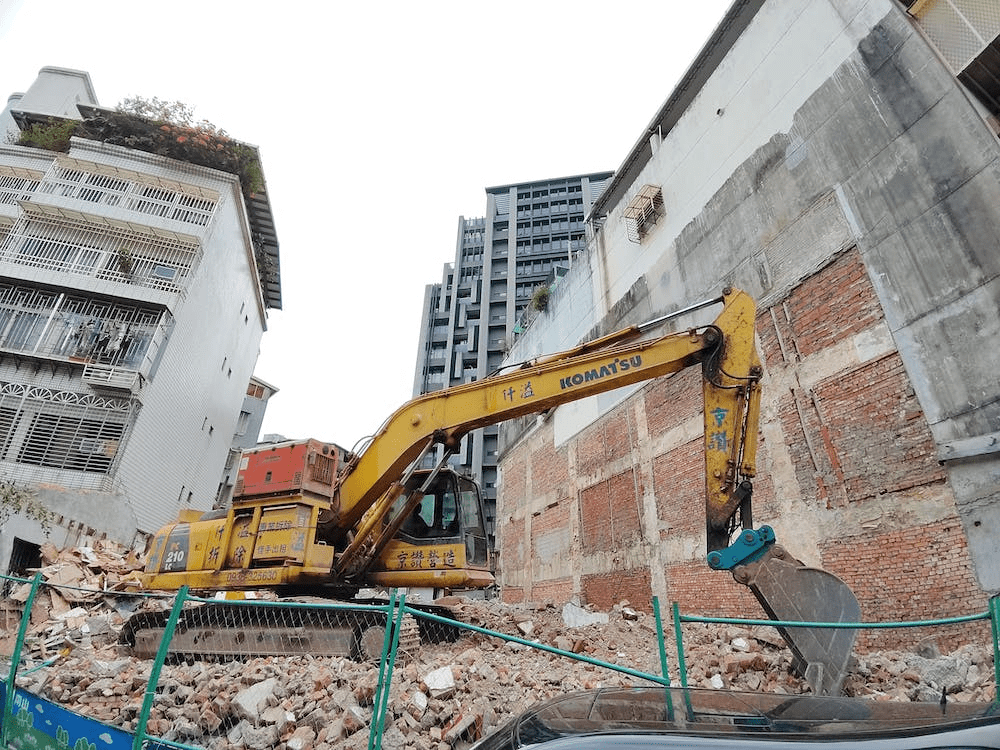

An asphalt crusher is a machine that breaks down asphalt and pavement materials into a more manageable form. It can process rocks, stones, and various recyclable materials such as concrete, asphalt, and glass.

Asphalt crushers reduce the chunks or pieces of asphalt by grinding them into smaller particles so they can be reused in road construction projects. The end product is aggregate material often used for road bases, parking lots, and driveways.

An asphalt crusher offers several possibilities for reusing valuable broken-down materials like asphalt and concrete. It is a cost-effective way of recycling asphalt and reducing waste in the environment with minimal environmental impact.

To learn about Concrete Crushing, Click here!

5 Practices For Crushing & Screening Using Asphalt Crusher

1. Inspect The Asphalt

Before beginning any work with an asphalt crusher, it’s critical to inspect the asphalt. Look for cracks, holes, or other damage that could cause problems during crushing or screening. If there is any damage, make sure to repair it before proceeding.

2. Set Up the Crusher

Once the asphalt is inspected and repaired, set up the crusher. This should be done in a way that will minimize dust and other debris from being generated. Ensure all safety guards are in place and all workers wear proper personal protective equipment (PPE).

3. Start Crushing & Screening

After the crusher is set up and all safety precautions have been taken, start crushing and screening the asphalt. Work slowly at first to ensure that everything is working correctly. If everything is going well, increase the speed of the process.

4. Monitor the Process

As the asphalt is being crushed and screened, monitoring the process closely is essential. This will help to ensure that all of the material is being correctly processed and that there isn’t any damage being done to the equipment. If anything appears to be going wrong, stop the process immediately and investigate the issue.

5. Shut Down & Clean Up

Once all of the asphalt has been processed, shut down the crusher and clean up any debris that has been generated. This includes large pieces of asphalt and more minor fines and dust. Make sure to dispose of all waste material in a safe and responsible manner

To learn about What Are The Pros & Cons Of Using Crushed Concrete? Click here!

The Benefits Of Using An Asphalt Crusher

1. Fewer Potholes

One of the primary benefits of using an asphalt crusher is that it can help to reduce the number of potholes in a given area. Potholes are formed when water seeps into cracks in the asphalt and then freezes, expanding and causing the cracks to deepen. Asphalt crushers can help break down larger pieces of asphalt into smaller ones, which can then fill in potholes.

2. Improved Drainage

Another benefit of using an asphalt crusher is improving drainage in a given area. Poor drainage is often a significant contributor to pothole formation, as water that pools on the surface of the asphalt will eventually seep into cracks and cause them to expand. By breaking down more significant pieces of asphalt, a crusher can help to create a more even surface that will allow water to drain more effectively.

3. Reduced Maintenance Costs

Using an asphalt crusher can also help to reduce maintenance costs in a given area. Potholes and other surface defects can cause damage to vehicles, which can require expensive repairs. By preventing pothole formation and improving drainage, an asphalt crusher can help prolong the pavement’s life and reduce the need for costly repairs.

4. Increased Recycling Potential

Asphalt is a recyclable material, but only if it is broken down into smaller pieces. Many recycling facilities cannot process more significant pieces of asphalt, so they must be sent to landfill instead. However, by using an asphalt crusher, larger pieces of asphalt can be broken down and then recycled rather than sent to a landfill.

5. Improved Aesthetics

Finally, using an asphalt crusher can also help improve a given area’s aesthetics. Potholes and other surface defects can spoil the look of an otherwise perfect pavement job. By breaking down more significant pieces of asphalt and filling in potholes, a crusher can help to create a smooth, even surface that will improve the overall appearance of an area.

To learn about the Limestone Crusher, Click here!

Tips For Maintaining Your Asphalt Crusher

1. Inspect Your Crusher Regularly.

Asphalt crushers are designed to break down asphalt to be recycled. However, the crusher can become worn down and less effective over time. That’s why it’s essential to inspect your crusher regularly and replace any parts that are worn out.

2. Keep Your Crusher Clean.

A dirty crusher can be less effective and even dangerous. That’s why it’s essential to keep your crusher clean. You can do this using a high-pressure washer or simply hosing it down with water.

3. Lubricate Your Crusher Regularly.

Another way to keep your crusher in good working condition is to lubricate it regularly. This will help prevent parts from becoming too dry and wearing out prematurely.

4. Check For Wear And Tear Often.

Even if you take good care of your crusher, it will still experience wear and tear. That’s why it’s essential to check for any signs of wear and often tear and replace any parts starting to show signs of wear.

5. Follow The Manufacturer’s Instructions.

As with any machinery, it’s essential to follow the manufacturer’s instructions when using an asphalt crusher. This will help to ensure that you get the most out of your machine and that you don’t damage it in any way.

To learn about the Gravel Crusher, Click here!

Conclusion

So there you have it – everything you need to know about asphalt crushers! We hope that this has been helpful and informative. Thanks for reading!

Moreover, if you still have any queries, you can contact us. Our team of experts will be more than happy to help you out.